A Game Changer Engine Technology

Superior Performance and Efficiency

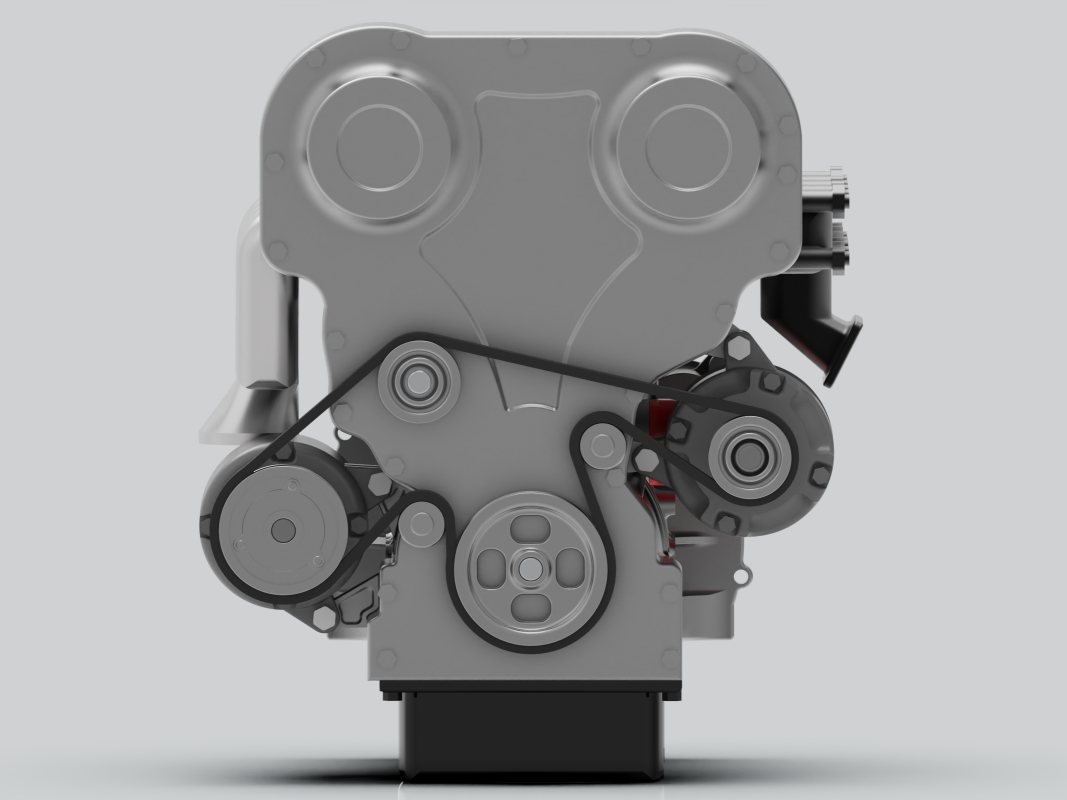

The Dynamic Flow engine, developed by Dynamic Alpha Automotive Technology (DAAT), represents a novel advancement in 4-stroke piston combustion engines. This innovative design offers several advantages over conventional engines. While the core operation remains similar to existing 4-stroke engines, key distinctions lie in airflow delivery, exhaust gas expulsion, and fuel injection strategies. This revolutionary approach unlocks a range of features and benefits, with the potential to transform numerous industries and contribute to a more sustainable future.

Feature

Advanced Valve Configuration:

Dynamic Flow 4-stroke engine high gas flow rate is comparable to 2-stroke engines, while the gas flow duration matches that of 4-stroke engines. This superior gas flow capacity translates to increased power output and enhanced efficiency.

Benefits:

The Dynamic Flow engine’s innovative valve configuration enables gasoline and diesel engines to reach exceptional thermal efficiency, achieving 48% or higher without performance penalty.

EIVC Atkinson Cycle:

Dynamic Flow 4-stroke gasoline or diesel engines can operate on the Atkinson cycle without incurring parasitic pumping losses, maximizing efficiency and allowing for effective turbocharger utilization. This propels Dynamic Flow 4-stroke engines to higher thermal efficiency limits.

Benefits:

The Dynamic Flow engine incorporates a groundbreaking method to simulate the Atkinson cycle in both gasoline (Otto) and diesel cycle engines. By integrating this Atkinson cycle feature, the engine’s thermal efficiency can be enhanced by an additional 12% to 27% beyond its existing peak efficiency of 48%, potentially achieving a peak thermal efficiency of up to 75%. This innovative approach also enables multi-fuel compatibility, preparing the engine to adapt seamlessly to future fuel options such as synthetic fuels, ammonia, and hydrogen.

Variable Displacement Feature:

This groundbreaking, first-of-its-kind feature harnesses exhaust gases to simulate varying engine size displacements by displacing intake air in the combustion chamber during the intake and compression strokes. This variable displacement capability allows the Dynamic Flow engine to dynamically adjust its size displacement (and power output) to match real-world load conditions, reducing fuel injection requirements during partial load operation.

Benefits:

For gasoline engines, this enables the Dynamic Flow system to maintain peak thermal efficiency across all partial load conditions, leading to significantly reduced fuel consumption. In diesel engines, it allows operation at stoichiometric conditions under partial loads, dramatically reducing emissions. The result is an engine capable of achieving peak thermal efficiency in all real-world scenarios, with emission control performance rivaling conventional engines equipped with external auxiliary exhaust after-treatment systems.

Want to know more about this engine in detail…

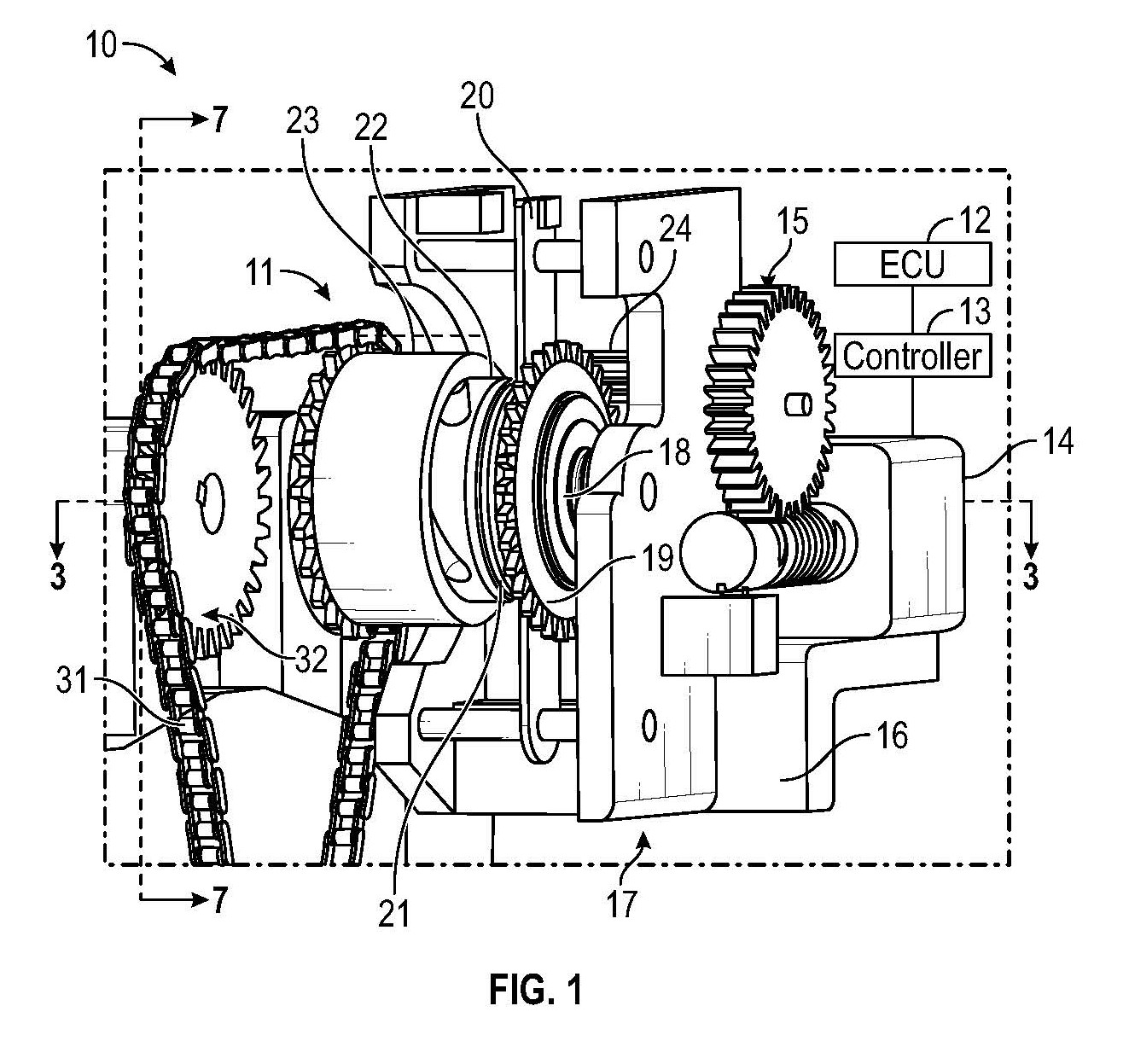

Advance Variable Valve Timing From

Dynamic Alpha

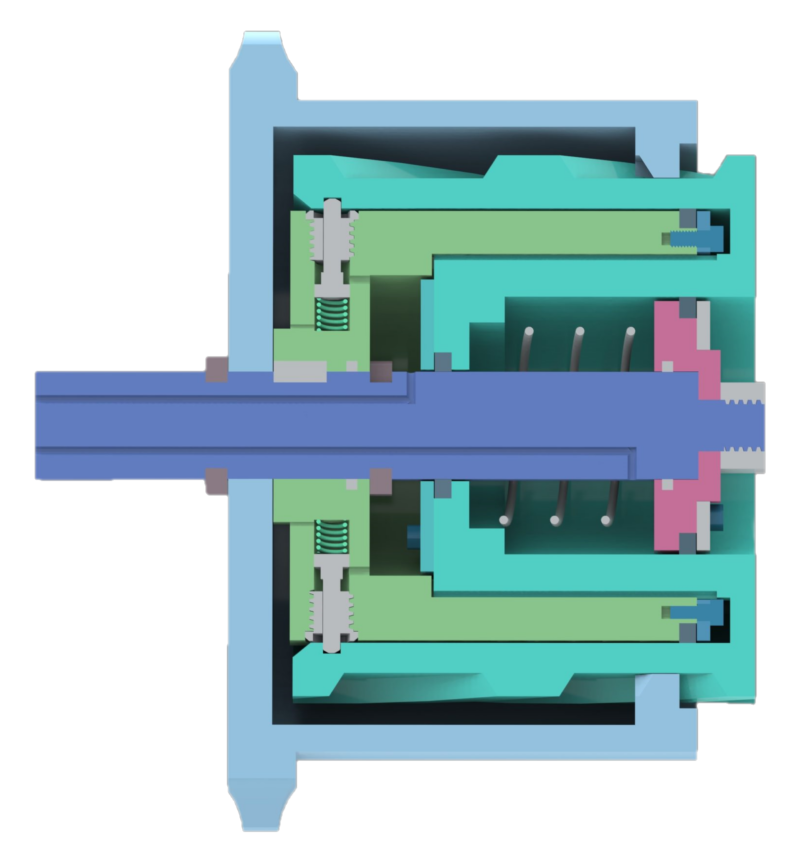

Variable valve timing (VVT) is a technology employed in modern internal combustion engines to optimize the timing of valve opening and closing.

This optimization enhances the engine’s ability to breathe air and fuel, leading to several key benefits:

- Increased Torque and Power: VVT allows for adjustments to valve timing that improve the engine’s ability to take in air and expel exhaust gases. This translates to increased torque and power output across the engine’s operating range.

- Improved Fuel Efficiency: By optimizing valve timing for different engine loads, VVT can improve combustion efficiency. This translates to better fuel economy, allowing the engine to achieve more work from every unit of fuel consumed.

- Reduced Emissions: Precise control over valve timing also enables VVT to contribute to lower emissions output. By optimizing combustion and minimizing incomplete fuel burn, VVT helps reduce pollutants like hydrocarbons and nitrogen oxides.